It's possible to improve fuel economy by 37 percent just by changing the way you drive, so hypermiling is gaining interest in light of high fuel costs.Now, I need to get this software working, but it's out of support. With CNC Machining requiring increasing levels of precision in even shorter times, it’s important to use a CAM Software that provides users with the features offered by HyperMILL.Hypermiling is a collection of driving techniques aimed at improving a car's fuel efficiency by reducing the demands placed on the engine. It is a modular and flexible CAM solution for 2.5D, 3D and 5-axis milling. HyperMILL is the complete CAM solution from OPEN MIND for NC programming. Thng tin lin h: Cng ty C phn Thng mi v Pht.

Hypermill How To Edit A

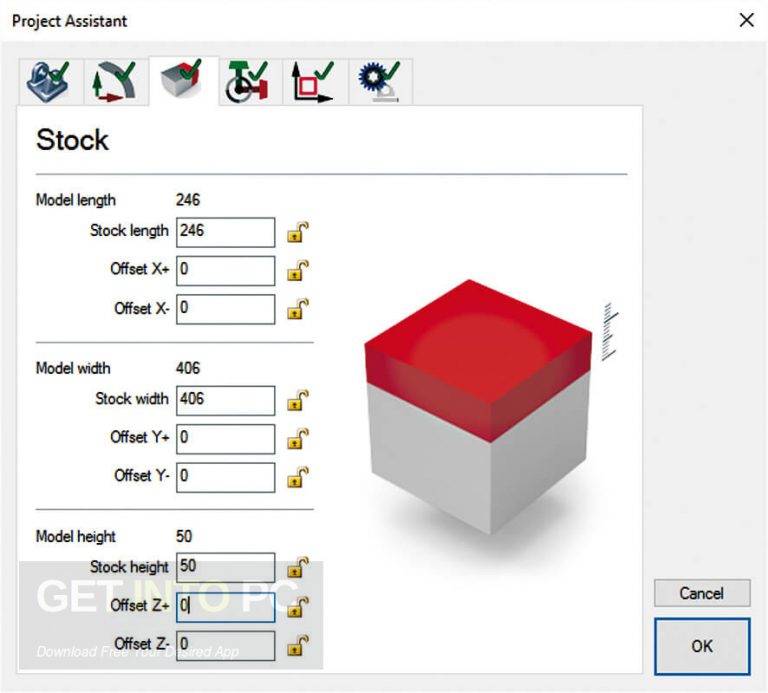

I have had a contact from one OM guy, who is looking for "a cost effective solution" for me, but I suspect this will be an upgrade or support contract which I'm not going to pay for, simply because there is no guarantee that the post will get sorted anyway, and the post should have at least worked in the beginning.HyperMill 2021.1 now offers an import function that retrieves face quality information and metadata when importing CAD data from neutral or native formats and attaches data to the imported faces in HyperCAD-S, making the information available to HyperMill and its machining processes.If anyone has worked out how to edit a Hypermill post I will be happy to hear from you, I need to get this working. If playback doesnt begin shortly, try. The OPEN MIND hyperMILL-to-VERICUT interface is available from OPEN MIND. The hyperMILL interface to VERICUT is supplied by OPEN MIND. Tool definitions, stock, fixture and design geometry from hyperMILL are automatically transferred to VERICUT.

They have now written a post that works correctly, with just a few minor tweaks needed, which we're working through.So, if anyone is looking to run a 3 or 5 axis machine with Xilog you can now use Hypermill to do it. Fortunately OM offered a solution - I agreed to a support contract ( which I wanted anyway to help my successors in this job ) and in return OM upgraded me to version 2018 and put their post team on the case. However, my Hypermill version was from 2005 and had no support contract since then, which put us both in a difficult position. Possibly because they weren't confident that the fault was with the post and not with themselves.Anyway, I presented the facts to OM, who studied the post and samples I sent and concluded that it didn't work correctly. As I wrote earlier, my predecessors for whatever reason didn't pursue a fully working post.

Employment Opportunity / RFQ (Request for Quote). I am lucky to have several metalworking machines by Bridgeport and Maier, so the cost is shared and makes more sense.If anyone wants to sub-contract CAD-to-XILOG work to me I'm open to offers. If I was buying cam for just a woodworking machine new, I probably wouldn't buy Hypermill, not because it isn't a great program, it is, but because the cost is so high.

0 kommentar(er)

0 kommentar(er)